The effects of climate change are being felt throughout the world. Meaningful, collaborative action is needed. We have set aggressive goals and are pursuing several priority pathways toward a low-carbon future. We are making steady progress toward our RE100 goal, and the Science Based Target initiative (SBTi) approved our near-term emission reduction targets in 2023, verifying that our near-term goals align with limiting global temperature rise to 1.5°C across all scopes. Our 2030 targets commit us to reduce Scope 1 and 2 emissions by 60% and Scope 3 emissions in Category 1 and Category 4 by 50% from a 2019 baseline.

Our Climate Strategy

Our climate strategy focuses on six critical areas where we can influence meaningful change:

- Energy Efficiency and Renewable Energy: The pathway to net zero starts with energy. We are working across our value chain to use less energy and shift toward renewables.

- Materials: Everything we make has an impact. We are prioritizing materials with lower impacts and finding ways to use less.

- Longevity and Circularity: We are challenging ourselves to break cycles of consumption that end at the landfill by making products that last longer and extending product use.

- Advocacy: We promote broader climate action by engaging governments to enact better climate policy, supporting advocacy groups and building climate awareness and action among our consumers.

- Land Use: Land use plays a central role in addressing climate change, so we’re working to eliminate deforestation throughout our supply chain and explore the role of regenerative agriculture.

- Low Carbon Transportation: Moving goods to global markets has a significant carbon footprint. We are improving our data systems to better understand sources of emissions and reduce them.

Carbon Emissions

Scope 1 and 2

In 2023, our total emissions from Scope 1 and 2 activities, which include those from our offices, distribution centers, retail stores, and owned-manufacturing sites, were 6,324 metric tons of carbon dioxide equivalent (MTCO2e). This is a 59% reduction from our 2019 baseline year, nearing our 2030 60% reduction goal. Looking closer, our Scope 1 and 2 emissions increased in 2023 primarily because of growth in the business. We saw total retail floorspace increase from 2022, which resulted in an increase in global electricity consumption. Some of these new locations were in regions where renewable electricity options are limited or had prohibitively high cost. In 2023, 90% of our global electricity use was sourced from renewables. We are still heavily reliant on energy attribute certificates, like Green-e certified Renewable Energy Certificates (RECs), I-RECs, and Guarantees of Origin (GOs).

Scope 3

Scope 3 emissions account for nearly 95% of our total climate footprint. In 2023, our total Scope 3 emissions were 1.2 million MTCO2e, and our biggest Scope 3 impacts are related to the energy used across our Tier 1 and Tier 2 supply chain, the materials we use to make products, product end of life, and the transportation of products around the world. Our Scope 3 reduction goal (50% by 2030) applies only to Categories 1 and 4, representing a combined 84% of our Scope 3 footprint in 2023. Overall, Scope 3 performance is not on track. Categories 1 and 4 decreased 3% from our baseline year and 22% from 2022. This decrease is primarily due to improved data quality and accounting methodologies. We are updating prior year inventories to better compare year-over-year progress against our target. Our most recent CDP Report has a full explanation of our carbon emissions and sources. In 2023, we received a B from CDP for carbon emissions, risks, and opportunities disclosures, and New Balance was recognized by CDP as a 2023 Supplier Engagement Leader for our work engaging with our suppliers to tackle climate change.

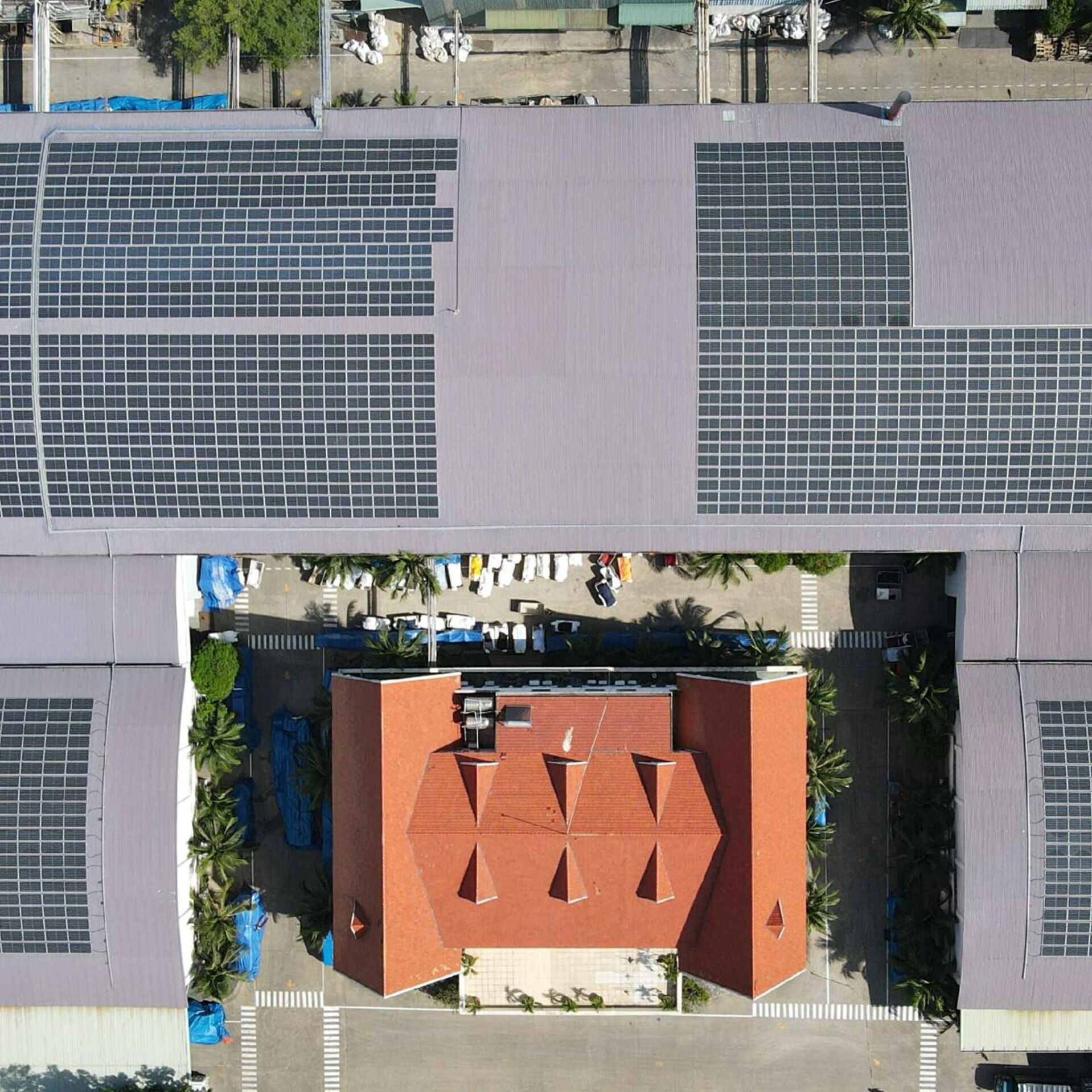

New Balance works closely with suppliers to improve energy efficiency and accelerate their transition to renewable energy. On-site solar generation is a highly effective way to reduce emissions at supplier factories. By working with organizations such as the Deutsche Gesellschaftfür Internationale Zusammenarbeit (GIZ) GmbH and the International Finance Corporation (IFC), we continued to support the development of on-site rooftop solar systems and provided climate action training to suppliers. In 2023, we worked closely with five sole suppliers to identify and execute energy efficiency projects under phase 3 of our engagement with IFC’s Vietnam Improvement Program. As an RE100 member, we are making steady progress toward our goal to source 100% renewable electricity for our owned operations by 2025. We source renewable electricity using several strategies, including generating on-site renewable electricity and purchasing Renewable Energy Certificates (RECs) and Guarantees of Origin (GOs). As part of Maine’s Net Energy Billing program, we joined a consortium of public and private buyers supporting the construction of four solar projects in Maine. If all four projects are successful, we expect to meet roughly 70% of the current electricity demand of our Maine facilities from these contracts.

We have ambitious goals that require collaboration to achieve them. New Balance is working with host governments and like-minded companies to accelerate deployment of clean energy in Southeast Asia through organizations like the U.S. Agency for International Development’s Corporate Clean Energy Alliance and U.S. Department of State‘s Clean Energy Demand Initiative (CEDI). We are active participants in important industry collaborations, like the UN Fashion Industry Charter for Climate Action and the Outdoor Industry Association Climate Action Corps. We have also been a proud member of 1% for the Planet since 2020. We donate 1% of sales from select product lines to support nonprofit organizations working on climate change and protecting public lands. Our current program runs through December 2025 during which New Balance donates 1% of MSRP from all Fresh Foam X Hierro v8 and Fresh Foam X Hierro GTX sold in the U.S. to 1% for the Planet, supporting Protect Our Winters and Trust for Public Land.

Leather tanning and textile processing can be water intensive, so we’re working with our material suppliers to understand and manage water impacts throughout our supply chain. We work closely with our network of suppliers to evaluate water risks, assess opportunities to reduce freshwater consumption, and ensure wastewater is safely returned to the environment from mills and tanneries.

Wastewater

The textile industry is considered one of the largest polluters of water globally. All wastewater from supplier manufacturing processes must be treated before being returned to the environment. New Balance played a leading role in developing the ZDHC Wastewater Guidelines. Launched in 2017, the guidelines serve as a cohesive standard that can be used industrywide. Our suppliers undergo testing twice a year to ensure their conformance with the guidelines. Our goal is to eliminate the discharge of hazardous chemicals by 2025, measured according to the ZDHC Wastewater Guidelines. As of 2023, 87% of our participating suppliers were in conformance. Of the suppliers that discharge directly into the environment, 93% were in conformance. In 2023, the most common violations occurred due to the presence of volatile organic compounds, organotin compounds, and other chemicals. In 2023, all suppliers with a violation performed a root cause analysis and implemented a corrective action plan.

IPE Screenings

We use the Blue Map Database, developed by the Institute of Public & Environmental Affairs (IPE), to screen China-based supplier facilities for any known violation records, including wastewater issues. Violations have been decreasing since 2018. In 2023, we identified 16 violations and collaborated with suppliers to determine the root cause, remediate, and achieve compliance. This diligence contributed to IPE ranking us 10th in their 2023 Green Supply Chain CITI Index report, out of over 700 companies operating in China across all industries.

We are challenging ourselves to break free from consumption cycles that end at the landfill. We’re developing products that last longer, repurposing factory waste into useful materials and finding new ways to recycle or extend the use of your New Balance gear when you’re done with it.

Zero Waste to Landfill from Footwear Factories

Making footwear can generate a tremendous amount of waste, often in locations without sophisticated waste management infrastructure. We’ve set a goal to achieve zero waste to landfill from all our footwear factories by 2025. Between our owned manufacturing and Tier 1 footwear suppliers, we generated approximately 18,000 metric tons of waste in 2023, and 70% was diverted from landfill. Reaching our goal is a massive effort that mandates change across the entire product creation process to reduce waste at the source and find ways to turn unavoidable waste into new materials.

Our factories build what we design. Some waste creation at the factory can be tied back to early decisions in the design process. To help reduce material waste at the factory, our internal design teams are rethinking how we design product to drive better material efficiency and eliminate unnecessary waste. When waste is created, we investigate closed-loop solutions that can allow it to be repurposed and turned into a new material or feedstock. We have introduced a regrind process with our suppliers in which post-industrial rubber waste and EVA waste are incorporated into some new outsoles and midsoles, respectively. In 2023 we trialed the use of recycled leather and initiated a development agreement with a leather supplier to convert leather waste from our owned factories back into a usable material. We are also pursuing textile-to-textile recycling opportunities for polyester textile waste, and in 2023 approximately four million pairs featured textile-to-textile recycled yarns.

Wear Longer, Waste Less

Our industry has a waste problem. For too long, we have consumed resources to produce short-lived goods without enough consideration of longevity and disposal. We’re working to change this. The most sustainable shoe is one that already exists.

Consumers have few options for responsible disposal when a product reaches the end of its life or they are simply done using it. While some individual materials can be recycled, the infrastructure and technology for recycling whole products — especially shoes — is still largely in its infancy. We are pursuing several initiatives to extend shoe lifetimes, including shoe repairs in Japan, a global donation program with Soles4Souls, and a new trade-in and resale program in the U.S. called Reconsidered. New Balance Reconsidered is one small step to try to keep some product in circulation longer. Through the Reconsidered program, New Balance products that have either been worn or are unsellable as brand new for cosmetic reasons are given another chance. In 2023, we also joined The Footwear Collective (TFC) to explore circular solutions with other footwear brands dedicated to scoping, developing, and scaling circular solutions.