Since 1906, quality has been our trademark. But we realize that every product we make has an impact, much of it determined early in the design process when we decide on materials, form, and construction. We are constantly finding new ways to manufacture more responsibly, including choosing more sustainable materials and exploring ways to keep products and materials in circulation as long as possible.

Environmentally Preferred Materials

Materials serve as the foundation for everything we create. Opting for the right material determines much of the performance, style, and cost of a product, as well as a major portion of its environmental impact. Every material possesses distinct performance characteristics and a unique environmental footprint. Our internal Environmentally Preferred Material (EPM) guide equips materials teams with preferred material criteria, aligning our approach to material creation across teams and driving progress toward our preferred material and science-based emission reduction targets.

Excluded from our environmentally preferred material goals (and progress against those goals) are licensed footwear and apparel, apparel designed and marketed by New Balance’s regional design centers (Tokyo Design Center and Manchester Design Studio), New Balance direct to team, promotional products ordered through third-party vendors, and global football apparel prior to 2022. Beginning in 2022, global football apparel was included, except New Balance Japan.

Polyester is our most commonly used textile material. It is durable, lightweight, and well-suited for many apparel and footwear, but it is conventionally derived from fossil fuels. Our goal has been to source 50% recycled polyester by 2025, and we achieved our goal in 2023 by sourcing 56% recycled polyester. This achievement demonstrates that meaningful, fast-paced change is possible. To align with our science-based targets and because we are tracking ahead of our 2025 goal, we now aim to source 100% preferred polyester by 2030, with an updated preferred polyester definition to include recycled, biologically derived, and emissions-based feedstocks. For recycled feedstocks, we have added a specific target to source 25% of our recycled polyester from textile waste.

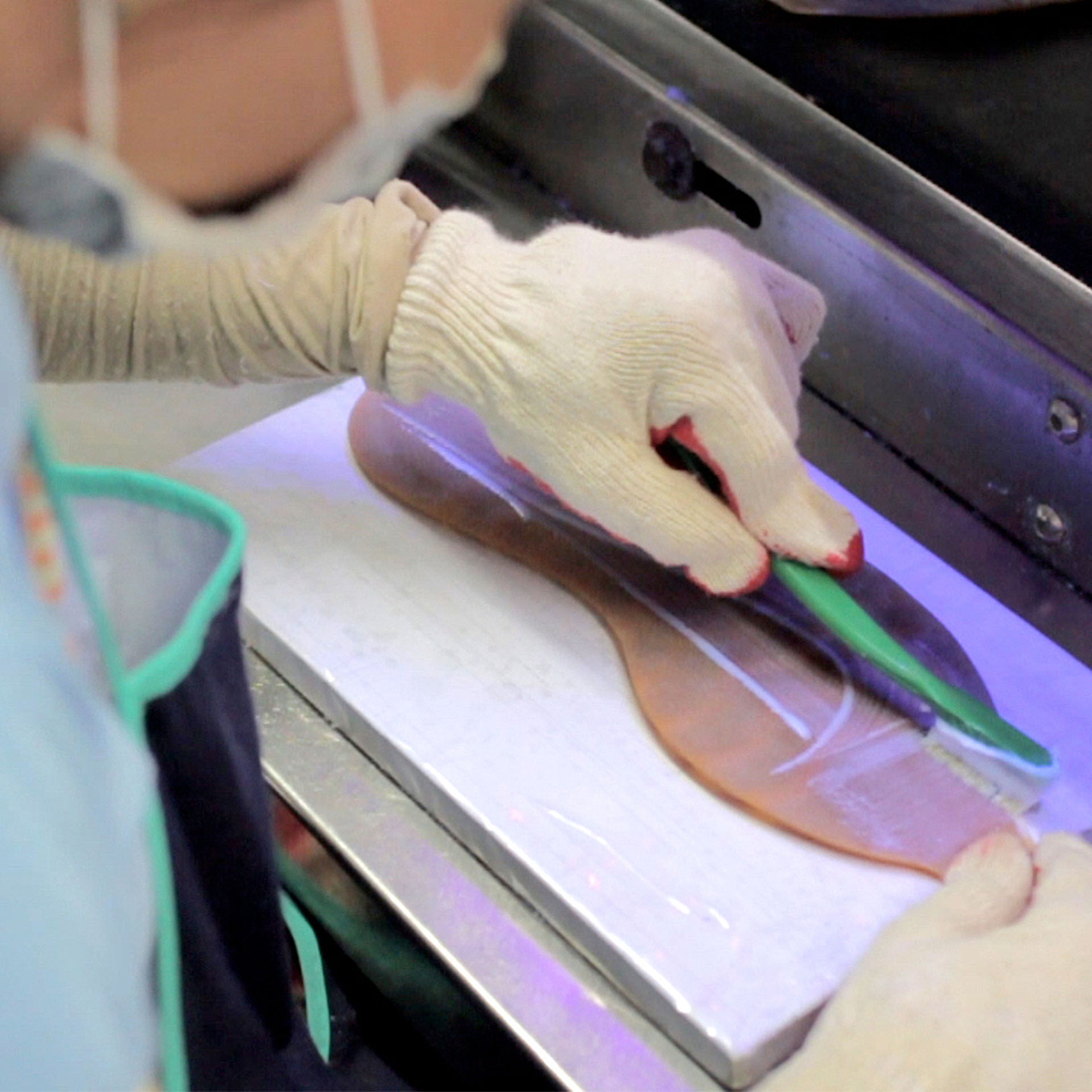

Leather is durable and comfortable, but its production can be land, resource, and chemical intensive. Our goal has been to source 100% preferred leather by 2025, with preferred leather being sourced from Leather Working Group (LWG) gold-rated tanneries, chrome-free, or sourced from ranches practicing regenerative agriculture. In 2023, we sourced 94% preferred leather. Starting in 2024, we are expanding our definition of preferred leather to prioritize lower emission sources and align with our science-based targets. Our updated leather goal is for 100% of our leather to be chrome-free, regenerative, or considered low emissions by 2030, with low emissions requiring an LCA showing an emissions factor less than 18 kgCO2e/kg material. Tanneries with an annual capacity over 1 million square feet must be LWG Gold-rated, and smaller tanneries with a capacity under 1 million square feet must be LWG audited. All the leather we use also meets our foundational Animal Materials Policy, found in our Restricted Substances Manual.

Cotton is a versatile and comfortable natural fiber. Nevertheless, its cultivation demands high volumes of water and agricultural chemicals and is linked to labor rights concerns. Our goal is to source 100% preferred cotton by 2025. Our preferred options include certified organic cotton or cotton sourced as Better Cotton. New Balance is a proud member of Better Cotton. Better Cotton is not physically traceable to end products. Buying products that were sourced as Better Cotton creates demand and directly invests in improving conditions at the farm level. Learn more at www.bettercotton.org/massbalance. In 2023, we sourced 38% preferred cotton. This was a significant decline from 2022. We are reviewing and revising our cotton calculation and related processes. Looking forward, we also plan to facilitate circularity by moving away from cotton blends that are difficult to recycle, such as polycotton.

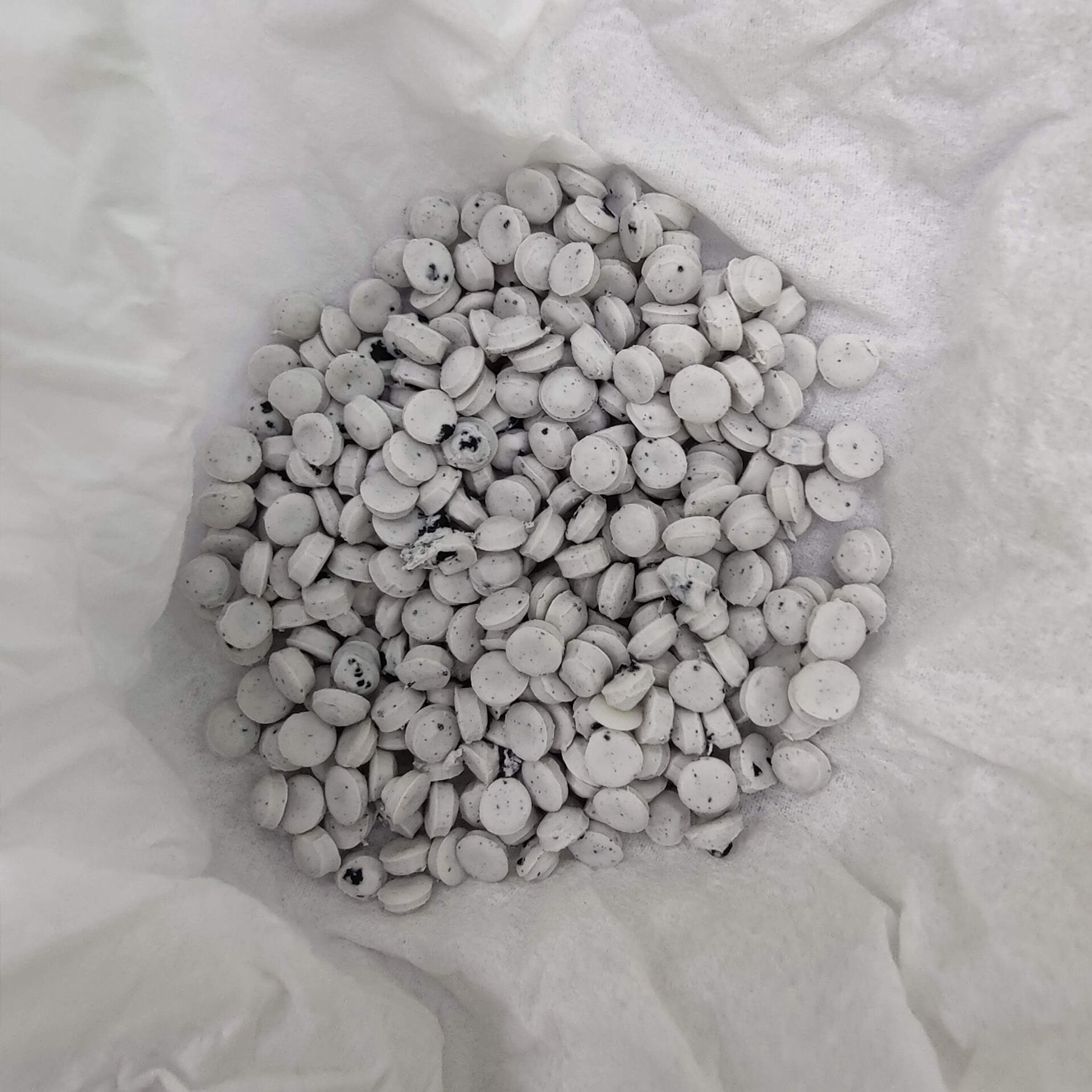

Shoe soles contribute a significant portion of our materials demand and related impact. In 2023, we defined our preferred sole materials and processes and set a new target to minimize our impact. Our goal is to source 80% preferred midsole and 90% preferred outsole compounds by 2030. Our preferred midsole material is bio-based EVA from sugarcane and recycled midsole foam, and our preferred midsole processes are injection molded and direct molded. Our preferred outsole materials are recycled rubber and bio-based compounds.

Shoe soles contribute a significant portion of our materials demand and related impact. In 2023, we defined our preferred sole materials and processes and set a new target to minimize our impact. Our goal is to source 80% preferred midsole and 90% preferred outsole compounds by 2030. Our preferred midsole material is bio-based EVA from sugarcane and recycled midsole foam, and our preferred midsole processes are injection molded and direct molded. Our preferred outsole materials are recycled rubber and bio-based compounds.

We are continuously working toward eliminating hazardous substances to conserve healthy ecosystems and promote the health and safety of consumers and workers across our supply chain. Our product chemistry standards apply to all footwear, apparel, accessories and equipment that New Balance makes directly, at contracted factories and through our licensees.

We are continuously working toward eliminating hazardous substances to conserve healthy ecosystems and promote the health and safety of consumers and workers across our supply chain. Our product chemistry standards apply to all footwear, apparel, accessories and equipment that New Balance makes directly, at contracted factories and through our licensees.

Restricted Substances Program

The New Balance Product Chemistry Program promotes compliance with our Restricted Substances Manual (RSM). The RSM enables our suppliers to make safer, more sustainable chemistry choices and implement continuous improvement programs around chemical management. The RSM contains two lists of restricted chemicals.

1. The Restricted Substances List (RSL) prohibits substances in materials, finished goods, packaging, and chemical commodities.

2. The Manufacturing Restricted Substances List (MRSL). prohibits a broad range of chemicals used within the manufacturing process. New Balance suppliers are required to eliminate any use of MRSL-listed substances during manufacturing.

Together, these lists covers more than 380 substances and chemical groups identified by international regulations and recognized standards as chemicals of high concern. We seek input from external partners like AFIRM and ZDHC to help us decide on chemical restrictions and management best practices.

Since April 2013, we have played a leadership role in the Zero Discharge of Hazardous Chemicals (ZDHC) Roadmap to Zero Program, a coalition of major apparel and footwear brands and retailers that are committed to leading the transition towards zero discharge of the industry’s most hazardous chemicals.

Supporting Supplier Compliance

To ensure compliance with our standards and relevant regulations, our Product Chemistry and Responsible Leadership teams offer both online and in-person courses to train suppliers and provide additional resources on topics such as restricted substances, testing procedures, and chemical management best practices. Suppliers may also participate in our Chemical Management Certification Program. Certification signifies that the supplier has a strong internal program for managing chemicals and avoiding the use of restricted substances. As of 2023, we have certified 97 Tier2 suppliers, with 15 achieving gold, 30 silver, and 52 bronze. Currently, 20% of our suppliers are certified to one of these levels.

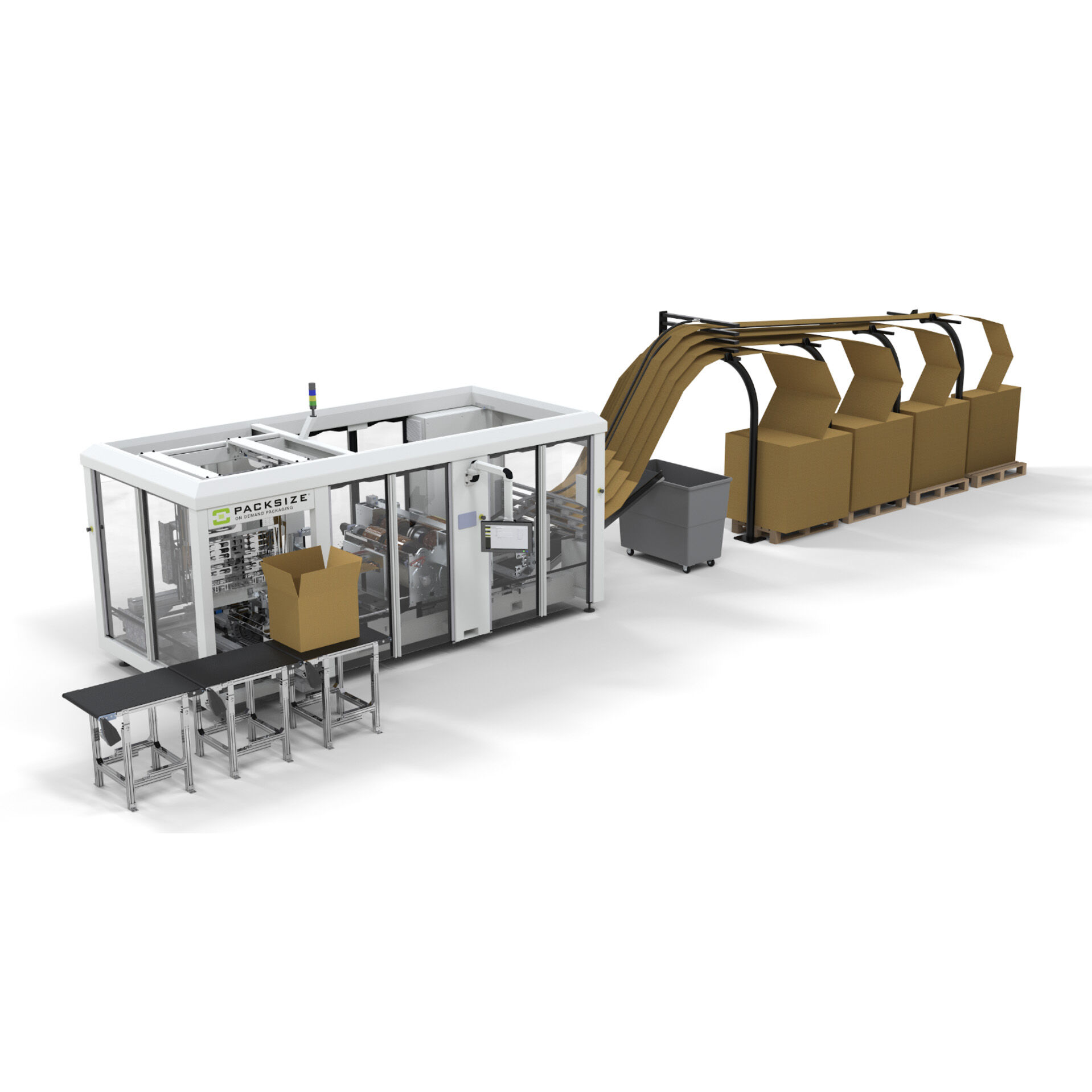

Packaging protects the integrity of our products, preventing damage during transportation. A damaged product anywhere along the way results in a substantial and avoidable waste of resources. We work to reduce the environmental impact of packaging while not losing sight of its most important function — protecting the product. PAPER: Most of our footwear packaging is paper based. Shoes are packaged in cardboard shoeboxes, wrapped in paper tissue to prevent discoloration, stuffed with paper tissue to maintain shape, and distributed in cardboard shipping boxes. One of our biggest concerns is the potential link to deforestation and land conversion. To reduce this risk, we prioritize use of recycled content and seek virgin content from certified programs that manage forests more sustainably, like Forest Stewardship Council (FSC). In our efforts to reduce paper usage and waste, we also implemented Packsize technology at our Nashville Distribution Center in 2023, which cuts corrugated cardboard into custom sizes. PLASTIC: All our apparel and most New Balance-branded accessories are individually packaged in plastic polybags, and small apparel orders are shipped to consumers in plastic shipping envelopes. In 2023, we continued testing paper-based bags and launched a small-scale consumer trial in Australia to gather feedback about an alternative shipping envelope made with Ocean Bound Plastic, a certified material made from recycled ocean-bound plastic pollution recovered from coastal communities throughout Southeast Asia.